300-800kg/h Fish Feed Production Line For Ghana Clients

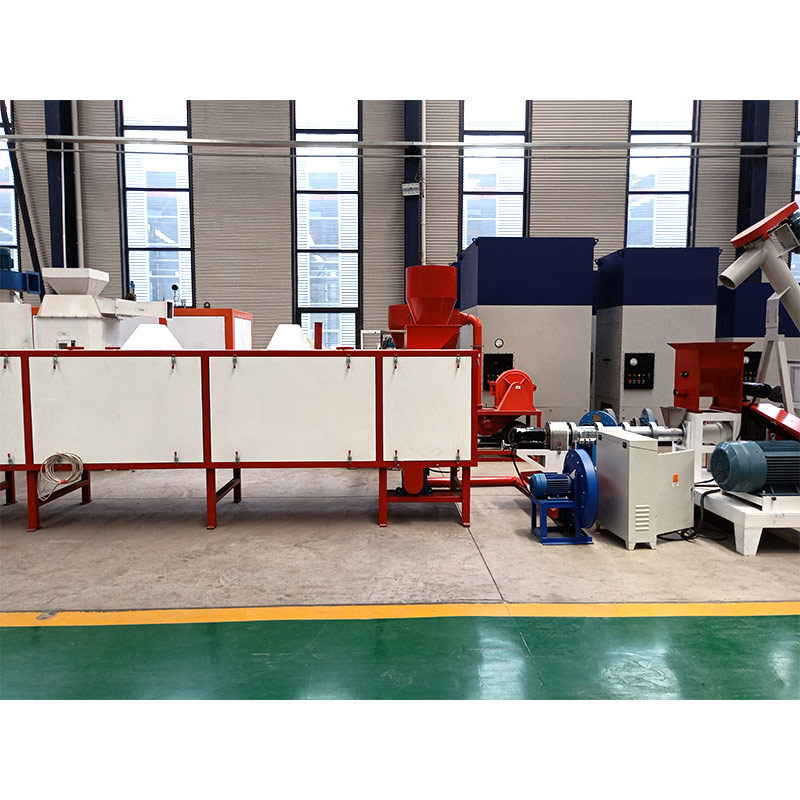

Automatic production line for commercial use

Capacity: 300-800kg/h

Produce: Floating fish feed, shrimp, turtle food, and also pets feed such as cats and dogs

Size: 30m*3m*5m (can adjustable)

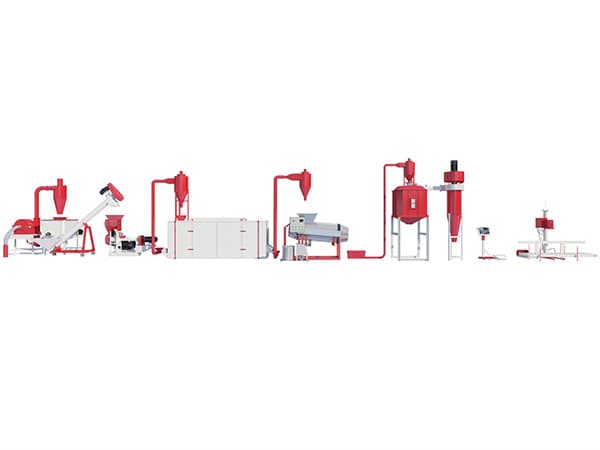

Including: crusher-mixer-extruder-dryer machines are the main and important machines of the production line, the extra machines such as conveyors, seasoning machines and air-flow conveyors are depends on clients’ options.

Functions of main machines in the production lines

Crusher: crush the materials into the required size of the formula

U-type mixer: fully mix all the materials evenly so that could get high-quality feeds

Conveyors: conveys the materials so that they can move to the next step to trail the production continues

Floating fish feed extruder machine: the main machine of the production line, the capacity of the fish feed extruder decides the capacity of the whole production line; it will make the powder materials into pellet

Air-flow Conveyor: help to convey pellet to the next process in case of broken the pellet, more hygienic and efficient

Dryer machine: usually the feeds will contain 25%-35% moisture after coming out from the extruder machine, the dryer machine is to reduce its moisture by under 12% to extend the storage time of the feed

Cooling machines: to achieve the purpose of drying, the pellet will go through the steam or high temperature, if they are stored or packed directly, the temperature will generate moisture and affect storage and packaging

Seasoning machine: it will help the pellet evenly spray seasoning oil or other additives to make the feeds more delicious and the fish prefer to eat

For crusher-mixer-extruder-dryer machines are the main and important machines of the production line, the extra machines such as conveyors, seasoning machines and air-flow conveyors are depends on clients’ options.

Raw materials

Corn, maize, soybean, rice, straw meal, grass meal, wheat chaff, groundnut cake, sunflower seeds , fish meal and so on;

What’s more, we can formulate recipes based on your existing materials.

Feature of this production line

Without some buffer bins, the height of the whole production line can be under 5m which is friendly to the one who has some height limited in their factory;

It can produce different size and shapes of pellet by changing the moulds. Th pellet can floating on the water over 24 hours;

Produce more pellet and wastes more fewer materials to make the production line more efficiency and high quality;

The material effectively kills harmful bacteria such as Escherichia coli and Salmonella by high temperature and high pressure, ensures the hygiene of the feed, facilitates protein denaturation absorption and starch gelatinization and is easy for fish and animal to absorb.

This feed is more easier for fish’s digest, and can easily observe the food consumption of fish without causing waste and pollution of feed.