40-300kg/h Small Fish Feed Production Line

Capacity: 40-300kg/h, 300-800kg/h, 1-3t/h,

Pellet Size: 0.8-12mm

Application: Catfish feed, Tilapia feed, Shrimp feed, Cat feed, Dog feed

Raw material: Corn, maize, soybean, rice, straw meal, grass meal, wheat chaff, groundnut cake, sunflower seeds, fish meal, etc

The sales manager can design fish feed production lines based on your conditions and needs

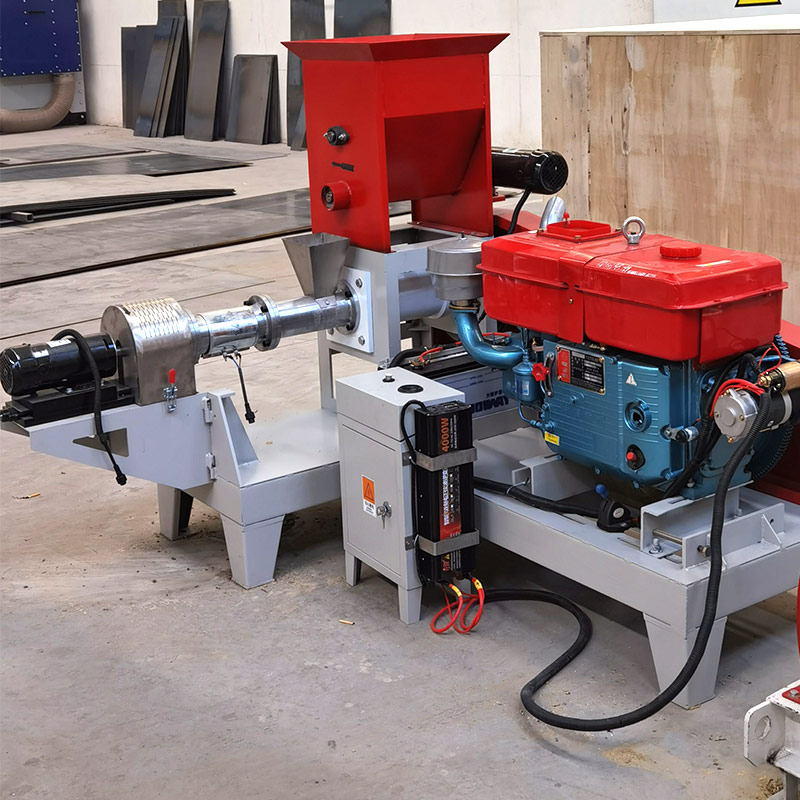

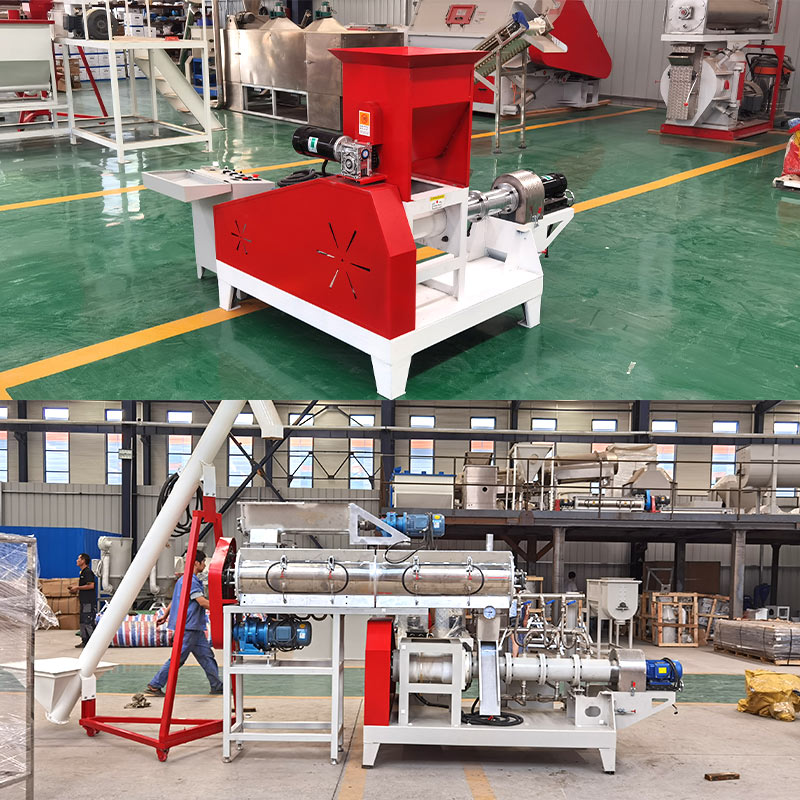

Small floating fish feed production line

According to clients’ needs, the crusher, mixer, extruder, dryer, and other necessary equipment constitute the whole fish feed production line. Users can use corn, soybean, wheat, grain, protein, fish meal, bone meal, and other raw materials to produce feed. The feed pellet has various shapes, unique flavors, and nutrient-rich, fine-textured granules, commonly used in catfish, tilapia, shrimp, cats, and dogs.

Fish feed grinder machine

A critical step in the production of fish feed is crushing the raw materials. The raw material’s surface area is increased during the crushing process, increasing the feed’s solubility in the digestive fluid and facilitating the animal’s digestion. At the same time, the quality and difficulty of following processing steps, including pelletizing, are also significantly influenced by the material’s particle size. Crushing efficiency is usually regarded by investors as an important metric to measure production cost, fish feed quality, and feed pricing because it accounts for 50 percent to 70 percent of the total power consumption of compound meal feed. Ingredients for all pelleted animal feeds, including corn, sorghum, grains, beans, broken cakes, and other materials, can be crushed by a fish feed crusher. It is especially made for finely grinding cellulosic materials as well as those that include a lot of water and oil. It is a crucial piece of equipment in the process of making floating fish feed, sinking fish feed, and pet food.

Fish feed mixer machine

The fish feed mixer is to mix various crushed raw materials. Mixers are essential in the feed production process, and effective mixing is the basis for high-quality feed output.

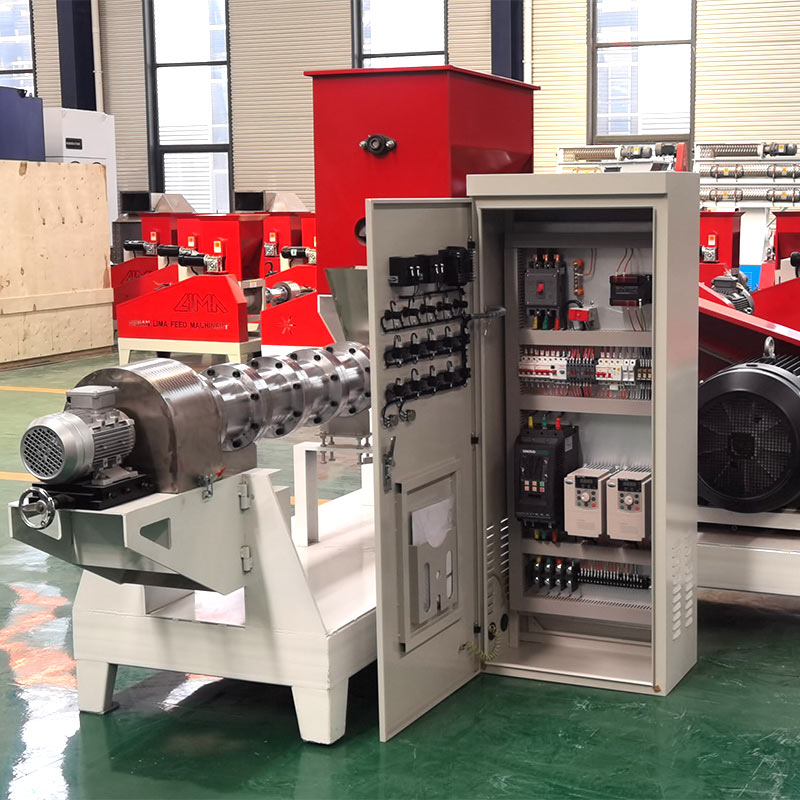

Fish feed extruder machine

A set of screws and sleeves on the extruder serve the purposes of mixing and twisting. The raw material is squeezed, rubbed, sheared, etc. between the screw sleeves once it enters the expansion chamber, and the internal pressure is steadily raised. The material’s structure changes as the temperature and pressure rise rapidly over the course of 3 to 7 seconds, further gelatinizing the starch, denatured the protein, obliterating the crude fiber, and eradicating dangerous germs like Salmonella. When the high-temperature and high-pressure materials exit the discharge port, the pressure is abruptly released in a split second, partially flashing the water. The material is loose and porous after cooling, and the expanded material is in the form of coarse chips, agglomerates, or flocs.

Fish feed dryer machine

To ensure the quality of the fish feed pellets and to improve the storage of fish feed, fish pellets should first be dried after being released from the fish feed pellet manufacturing equipment. You may dry the pellets more evenly by using the dryer machine.