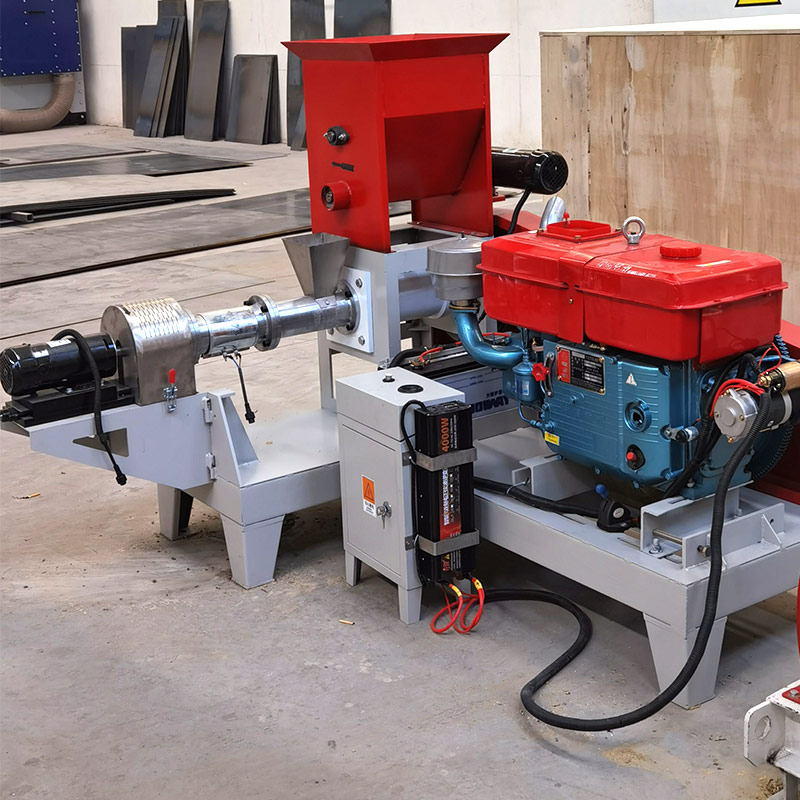

Testing Chicken Feed Machine For Ghana Clients

Capacity: 1-18t/h

Pellet Size: 2-8mm

Application: chicken feed, cattle feed, pig feed, sheep feed

Including: crusher-mixer-pellet machines are the main and important machines of the production line, the extra machines such as conveyors, seasoning machines and packaging system are depends on clients’ options.

Lima factory

Henan Lima Machinery Manufacture CO., LTD is a professional company in the design and research, manufacture, sales, and service of poultry machinery, such as floating fish feed pellet machines, chicken feed pellet machines, used in farm and big poultry feed factories widely, green food make your animal growing well. It is located in Zhengzhou City, Henan Province, which is known as China’s most significant agricultural province.

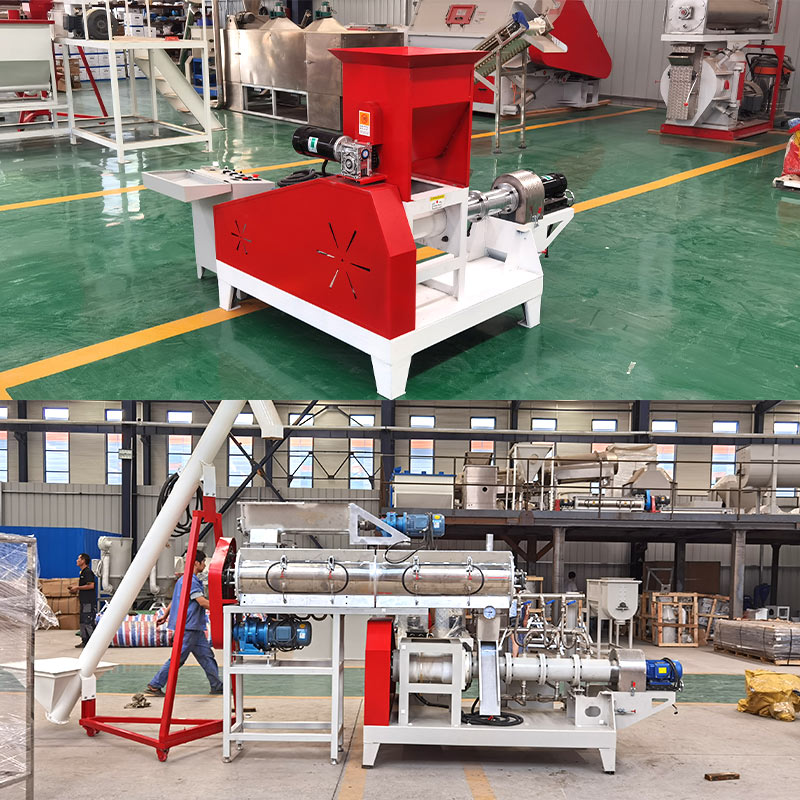

Ring Die Chicken Feed Pellet Machine

Ring-die chicken feed pellet machine is widely used to produce pellets for animals,such as chicken,pig,horse,cattle and other poultry and livestock animal.It mainly suitable for large farms and feed plant,it is an important part of poultry feed production line. This ring-die chicken feed pellet machine has various production capacity from 1ton/h to 18ton/h,which is large capacity on the base of production.

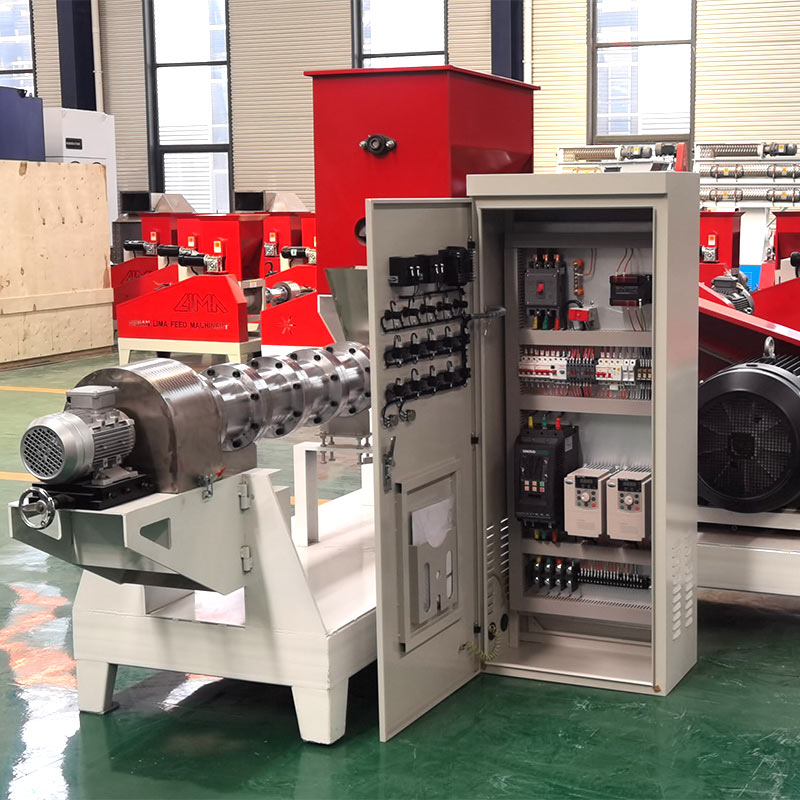

Structure of ring-die chicken feed pellet machine

This ring-die chicken feed pellet machine is mainly composed of the power unit,inlet an outlet,Stainless steel modulator,Among them,the power unit can be driven by a Siemens electric motor.The size of the discharge port can be customized according to customer needs.

Features

- From CPM model,European and American type cabinet;

- The main drive adopts high-precision gear transmission,and the forming box is made of stainless steel, and the output is increased by about 20% compared with the belt transmission type;

- Imported SKF high quality bearings and imported oil seals to ensure efficient,stable and low noise operation;

- Feeder adopts frequency conversion motor to ensure the quality of particle discharge;

- A variety of aperture, material, compression ratio ring die for selection, high quality process ring die, long service life, smooth grain, high quality;

- International high-level compression type serpentine spring coupling, with novel structure, compact,safe, low noise and low failure performance.