How To Distinguish The Quality Of Fish Feed Pellets?

In recent years, with the increasing popularity of high-yield fish farming, the use of full-price pellets for fish in fishery production has become very common. However, due to the many feed brands on the market, and there are great differences in quality and grade, the majority of fish farming The user cannot judge the quality of the fish feed pellets. This article introduces a simple method to judge the quality of fish feed using the senses. Namely:’One look, two smells, three twists, four foams, five chews’ for your reference when choosing fish pellet feed.

1. Look

1. Look at the color of fish feed pellets:

The pellet feed for fish is made of several main raw materials such as fish meal, soybean meal, cotton meal, rapeseed meal, secondary meal, meat and bone meal, etc., which are uniformly mixed and granulated in a certain proportion. The color of the finished product can reflect the amount of raw materials used to a certain extent. If there are more fish meal and soybean meal, the color of fish material will be slightly yellow; if there are more miscellaneous meal, the material color will be dark red; if there are more sub-meal, the material color will be slightly gray and so on.

2. Look at the fish feed pellets size:

Fish feed is the pellet formed after the pelleting process. By observing the particle size, it is possible to judge the ratio of the original particles, the fineness of the original particles, the uniformity of quenching and tempering, the granulation process and the selection of the ring die. The grain size of high-quality fish feed is uniform and smooth, the section is neat, the length is 1.5-2 times the diameter, and the powdering rate is not more than 1%; It is estimated to be caused by the following reasons:

(1) The fineness of raw materials is not enough

(2) The ratio of raw materials is unreasonable,

(3) Uneven quenching and tempering,

(4) Improper selection of ring molds,

(5) Improper adjustment of the cutter distance, etc.

3.Look at the gloss of fish feed pellets:

The surface of the pellets of high-quality fish feed is smooth, uniform and shiny. Such feed has good palatability, storage durability and high utilization rate.

The surface of inferior fish feed is rough and dull. The above phenomenon is mainly caused by the following reasons:

(1) The fineness of the raw material is not enough,

(2) Improper compression during the granulation process,

(3) Insufficient addition of feed oil and so on.

4. Look at the sinking speed of fish feed pellets:

When feeding pelleted fish feed, it is necessary to ensure that the feed has a certain buoyancy and sinking speed. The fish eat on the surface of the water body, which not only saves the feed but also facilitates the observation of the fish’s feeding situation. Generally fish feed should be guaranteed to float on the water surface for 3 to 4 seconds. If the water sinks too fast, the fish will not have time to eat, which will cause waste; if the floating time is too long, it proves that the feed contains more crude fiber and is of poor quality.

2. Smell the fish feed pellets

Pellet fish feed is made by mixing various raw materials and then steam conditioning and maturation. After the raw materials are matured, they will emit a unique fragrance. Grab a handful of freshly opened bag of feed and smell it in front of your nose. If you find moldy, bitter, burnt, artificial fishy, raw fish meal, and raw flour flavors, it indicates the following problems during processing

(1) Poor quality of raw materials,

(2) Excessive moisture content, deterioration during storage,

(3) The tempering temperature is inappropriate and so on.

3. Twist the fish feed pellets

Fish feed needs to be transported many times from production to feeding, and objectively requires a certain degree of mechanical strength. Under normal circumstances, a few twists with your fingers do not break, but it should not be too hard. If the feed is broken with one twist, it means that the feed is not hard enough, and the powdering rate is high during transportation, which is easy to cause feed waste; the hardness is too large and the palatability is poor, which affects the movement of the feed in the digestive tract and easily causes fish enteritis.

4. Bubble the fish feed pellets

Putting the feed into the water soaks it, on the one hand, it can check whether the physical properties of the feed can meet the needs of the fish digestive tract. On the other hand, the approximate composition of the raw materials can also be analyzed. The specific method is to grab a handful of feed and put it in the water and observe the time for the feed to disperse. Generally, the feed is completely dispersed after 3-5 minutes. If the dispersal time of the feed is too short, it will easily cause the fish’s digestive tract to swell and affect its food intake. ; The feed disperses for too long, which affects the intestinal peristalsis of fish, and is not conducive to fish digestion and absorption.

5. Chew the fish feed pellets

Although the fish feed is swallowed, the quality of the taste is the main factor that affects their feeding behavior. Through the touch and taste of our oral cavity, we can feel the hardness of the pellets and the presence or absence of peculiar smell, whether the feed has deteriorated, whether the feed is mixed with impurities such as sand, soil and so on.

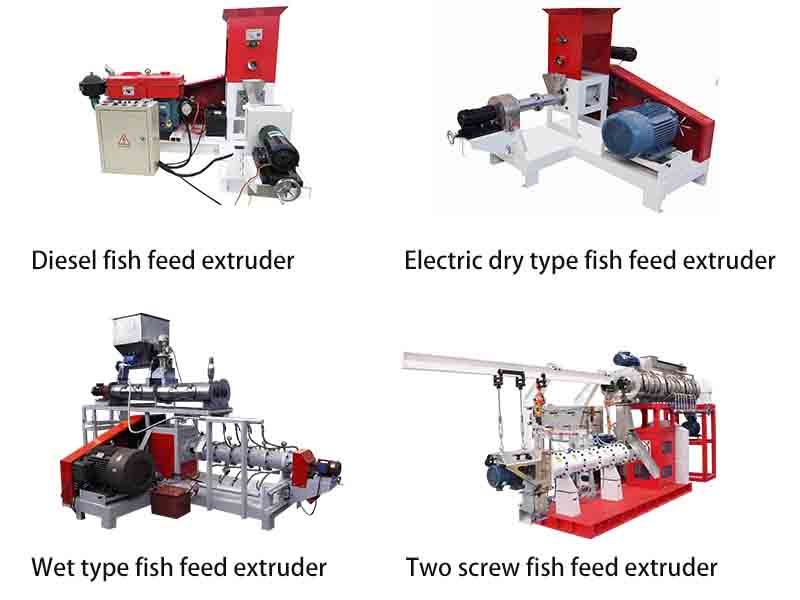

Established in 2006, Henan Lima Machinery Manufacturing Co., Ltd. is a professional food machinery manufacturer and exporter of fish feed machinery and fish feed production lines.

If you want to produce high-quality fish feed, please contact us, each of our floating fish feed machines comes with more than ten latest fish feed formulas, and we also have a professional team to provide you with installation, commissioning and maintenance services

Back to List