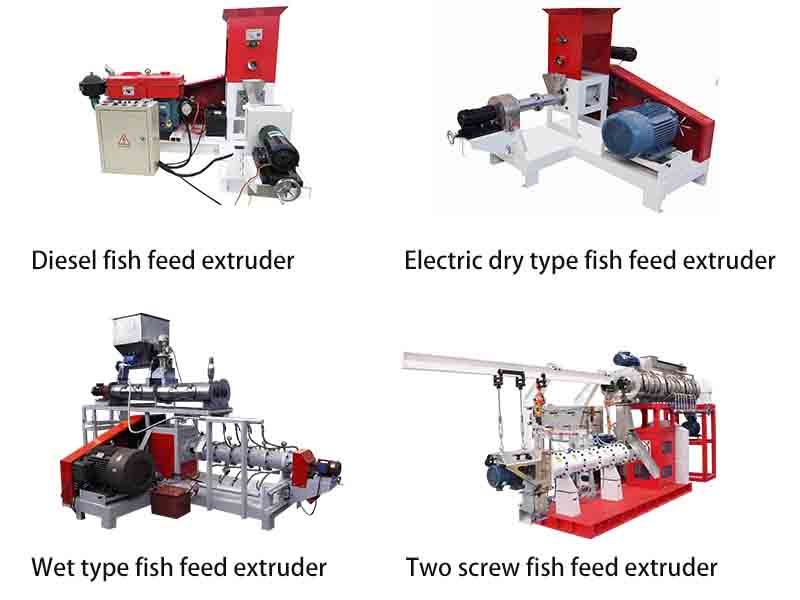

Types of fish feed extruders

Fish feed extruder machine can be divided into wet type fish feed extruder and dry type fish feed extruder . According to screw classification, it also can be divided into single screw fish feed extruder and twin screw fish feed extruder.

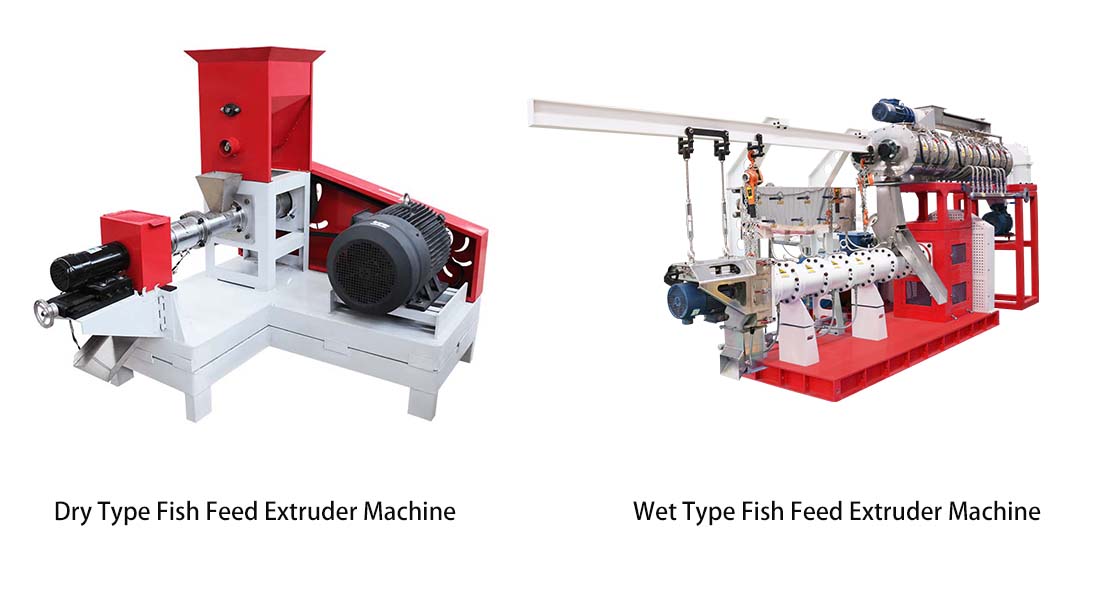

1. Wet type fish feed extruder

Wet type fish feed extruder is mainly used for extruding aquatic feed and pet feed food.

As an important equipment for fish feed production, the wet fish feed extruder is equipped with a steam boiler, which can continuously provide hot steam and effectively control the extrusion temperature. It can produce various floating or submerged aquatic feeds such as fish, eels, shrimps, crabs, loaches, bullfrogs, etc. It can also produce various pet feeds such as cats and dogs. The particle size can be from 0.5-15mm, feeding fish of different sizes. Wet sinking and floating fish feed extruder is the first choice for large and medium-sized feed processing plants and farms.

2. Dry type fish feed extruder

The dry type fish feed extruder does not require a steam boiler, and the dry type does not require external heating. Through the high temperature and high pressure of the raw material in the screw, heat is generated and accumulated during the rotating work in a closed environment. During high temperature curing, starch and fiber stock expand. The material is then formed into pellets through a forming die under pressure-sealed conditions. Finally, through the regular rotation of the screw, after being cut by the front knife, the finished product shrinks into an average small puffed ball under normal temperature and pressure.

Dry type fish feed extruder machines are widely used in small and medium aquaculture, grain and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants.

3. The difference between wet type fish feed extruder and dry type fish feed extruder

1). The dry fish feed extruder does not need a steam boiler, so the dry fish feed pellet machine is cheaper and easier to operate.

2) Compared with the dry type extruder, the feed pellets produced by the wet type fish feed pellet machine are smoother and of better quality because the fish feed raw materials are fully matured and mixed in the conditioner.

3) The capacity of dry type fish feed pellet machine is lower than that of wet type fish feed pellet machine, so usually dry type fish feed pellet machine is better and more economical for small and medium users or factories

4. Single screw fish feed extruder machine

The single screw fish feed extruder has a simple structure and is easy to operate. It is mainly composed of an electrical control cabinet, a cutting motor, a heating plate, an extruding chamber, a feeding device, a feeding motor and a main motor. The single screw extruder for the production of feed consists of a screw rotating in a heated barrel. It is widely used because of its simple structure, easy manufacture, high processing efficiency and low price. It is the most mature type of extruder with the largest consumption.

5. Twin screw fish feed extruder machine

The twin-screw fish feed extruder adopts the high-quality screw barrel and suspension design of international leading technology to reduce the friction between the barrel and the screw. It is more widely used and more economical than single-screw extruders. Compared with single-screw extruder, the starch structure in the raw material changes during the production process of twin-screw extruder and becomes easily absorbed nutrients. The quality of feed produced by twin-screw extruder is better than that of single-screw fish feed extruder.

Compared with the single-screw fish feed extruder, the twin-screw extruder solves many disadvantages such as low production volume, low extruding efficiency, difficult cleaning, limited nutrient addition, fast screw wear, and high cost of accessories.

Whether it is dry process fish feed extruder, wet process fish feed extruder, single screw fish feed extruder or twin screw fish feed extruder, the motor of the floating fish feed extruder has diesel and electric for your choice, whether it is a diesel engine or a electric engine, it can be customized according to your requirements.

All the fish feed machine accessories are all self-produced by Lima machinery and guaranteed after sale. When you buy our feed machine equipment, we will provide you with at least 3 grinding tools free of charge for you to produce fish feed pellets for different growth stages such as small, medium and adult fish.

Back to List