How To Make Floating Fish Feed In Ghana

1. Huge development potential of fish feed market in Ghana

Ghana’s fisheries and aquaculture industry is very developed, Ghana has good aquaculture conditions, has an ideal climate for farming tilapia and many other fish species, good water quantity and quality. The study found that about 2.6 million Ghanaians (10% of Ghana’s population) depend on fishing for their livelihoods. With a coastline of 550 km from Aflao in the east to Semi-Assini in the west, coupled with the aquaculture potential of the rest of the country, there is no doubt that Ghana’s aquaculture potential is huge.

Ghana’s fisheries are made up of industrial, semi-industrial and purely human fishing. Human-only fishing provides most of the country’s fish. It has been determined that if Ghana can maximize its fisheries potential, it has the potential to export approximately EUR 128 million of fishery products annually to the European market. Therefore, Ghana’s fisheries and fish feed process industries have great potential for development. There are very large investment opportunities in fish farming, such as production of fish feed, raising and stocking of high-quality fingerlings, and training and capacity building in fish farming.

2. The ingredients of floating fish feed

If we want to produce floating fish feed in Ghana, we first need to know the ingredients of floating fish feed. Different growth stages of fish require different protein content, and the formula of floating fish feed is also different.

(1)Small fish formula: Protein level: 34-36% ,

Raw materials: maize powder:30%, fish meal:20%, rice bran:5%, soya flour:30%, bone powder:2% ,wheat bran

powder:13%

(2)Medium fish formula: Protein level :30%

Raw materials: maize powder:30%, fish meal:15%, rice bran:10%, soya flour:25%, bone powder:2%,wheat bran

powder:18%

(3)Big fish formula :Protein level:28%

Raw materials: maize powder:35%, fish meal:15%, rice bran:10%, soya flour:20%, bone powder:2%,

wheat bran powder:18%

3. Buy floating fish feed extruder Ghana

Knowing the ingredients of floating fish feed, then you need to buy floating fish feed extruder in Ghana. Floating fish feed extruder machine can be used to produce (floating) extruded aquatic feed and extruded animal feed, as well as extruded pet food. With floating fish feed extruder, it is possible to use cheap fish feed raw materials in Ghana to produce high-quality feed and reduce feed costs. You can buy the fish feed extruder locally in Ghana or from abroad. The fish feed machine purchased locally in Ghana is cheaper, but the technology level is relatively backward, and the quality of the fish feed produced is average. The best way is to go abroad to purchase fish feed making machines. The earliest fish feed pellet machines are from European countries with more advanced production technology, but their fish feed extruder machines are too expensive. The most cost-effective fish feed extruer machines are Chinese fish feed machines with moderate prices and advanced machine technology.

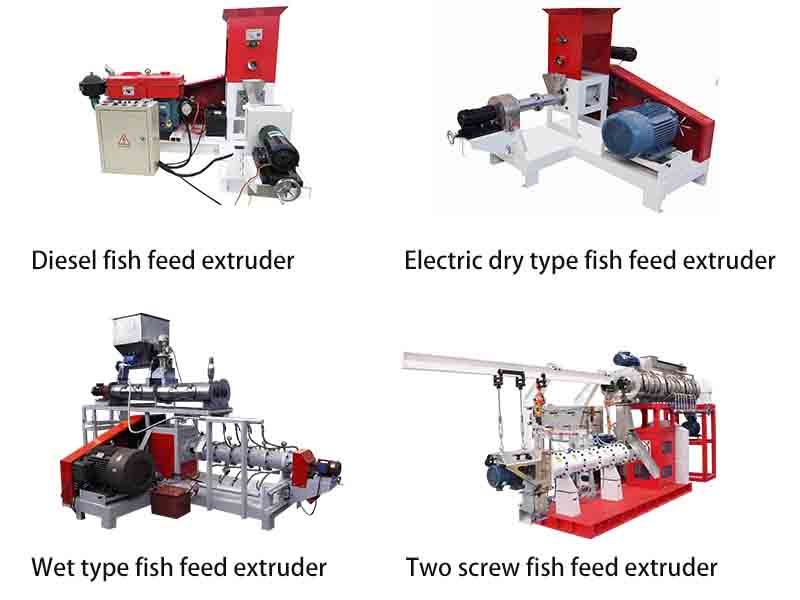

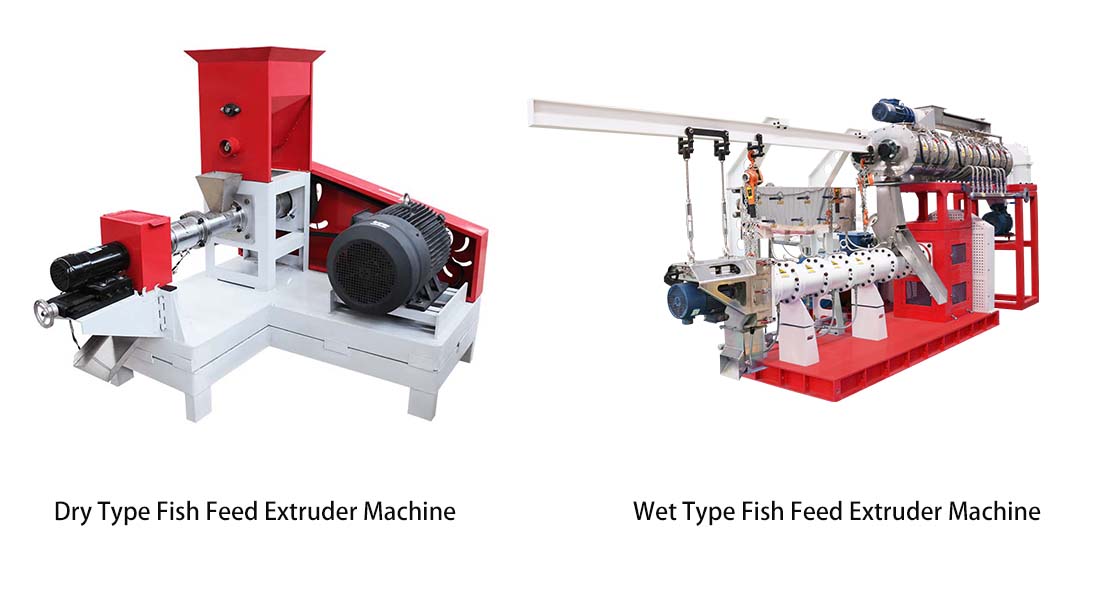

4. Types Of Floating Fish Feed Extruder Ghana

There are diesel floating fish feed extruder has and electric fish feed extruder. The functional parameters of the two types of fish feed extruder machines are basically the same, but the starting energy is different. You can choose according to the local energy situation in Ghana.

According to the production process, the fish feed extruder has a wet way fish feed extruder and a dry way fish feed extruder. Generally, Ghanaian households or small farms use the dry method. The wet method has one more boiler with steam than the dry method. The production process is more complicated and the price is more expensive, but the feed has a higher degree of maturation. The fish feed produced quality is also higher. If you want to set up a fish feed factory in Ghana, you can choose a wet way fish feed extruder

According to the product structure of fish feed extruder, floating fish feed extruder has twin-screw and single-screw extruder. For general aquatic feed production, single-screw extruder is sufficient. Twin-screw extruder is suitable for the production of various The factory purchase of animal feed, one is because the twin-screw extruder is more expensive, the other is because the twin-screw extruder is generally used to produce pet feed with higher fat content, and the twin-screw extruder has a larger output and higher production efficiency.

5. Ghana floating fish feed extruder production process

Basically, the floating fish feed extruder has a long barrel with an auger specially designed to expose the incoming fish feed mixture to high temperatures and steam pressure. When the fish feed comes out of the mould at the end of the barrel, the trapped steam is quickly blown away, and the soft warm pellets expand, producing low density floating fish feed pellets.

The fish feed extruder has a wide range of uses and can be made into a variety of feeds with different characteristics. The puffing and cooking process results in a lot of starch gelatinization, so the feed has good water stability. It can produce both “extruded” floating feeds and sinking feeds. The process also increases the digestibility of the product.

Floating fish feed saves 10%-20% of raw materials than sinking fish feed. Even the remaining part of the feed can be picked up and dried, which can highly control the waste of feed. Floating fish feed is easy to observe and control, reduce or avoid the pollution of water body by powder and residual bait, which is very beneficial to environmental protection and fish growth.

6. Equipment required for floating fish feed production in Ghana

Floating fish feed extruder is an essential machine for producing floating fish feed.

(1) In addition to floating fish feed extruder, a fish feed pulverizer is generally required: used to grind fish feed grains and other raw materials into fine powder. The smaller the grinded particles, the better the quality of fish feed. higher.

(2) Floating fish feed mixing machine: mix the raw materials of fish feed evenly and fully mix them together, the more evenly the raw materials are mixed, the nutritional content of a single fish feed pellet will be comprehensive, and the quality of fish feed will be higher.

(3) Fish feed drying cooler (fish feed): The feed is produced by high temperature and high pressure after entering the fish feed extruder. The temperature and humidity of the fish feed from the extruder are very high, so it cannot be packed by Lima. It is necessary to use a fish feed drying cooler to reduce moisture and lower the temperature.

(4) Fish feed packaging machine: drying and cooled fish feed can be quickly packaged with a packaging machine, which improves production efficiency and reduces labor costs

In short, a complete floating fish feed production line, in addition to fish feed extruders, requires fish feed pulverizers, mixers, dryers, packaging machines, etc. The purchase of auxiliary machines can be determined according to your own budget. If the budget is not very sufficient, you can purchase floating fish feed extruder production first, and then expand the scale and choose other auxiliary equipment for fish feed production. Please contact us to provide fish feed production solutions if you want to make floating fish feed in Ghana!

Back to List