What are the advantages of twin screw extruder?

With the emergence of twin-screw extruder machines with large specifications and large output, the use of twin-screw extruders can achieve greater production efficiency and give full play to the advantages of extrusion technology. The double screw extruder machine has a wide range of raw materials, high starch gelatinization degree, much higher water stability than ordinary pellet feed, adjustable product density, and can process floating, slow-sinking, fast-sinking feeds, and high moisture, high grease Feed, the particle structure is relatively loose, which is conducive to the use of post-spraying technology, avoiding the loss of heat-sensitive raw materials, preventing environmental pollution and disease resistance, improving the nutritional value of feed, and reducing production costs.

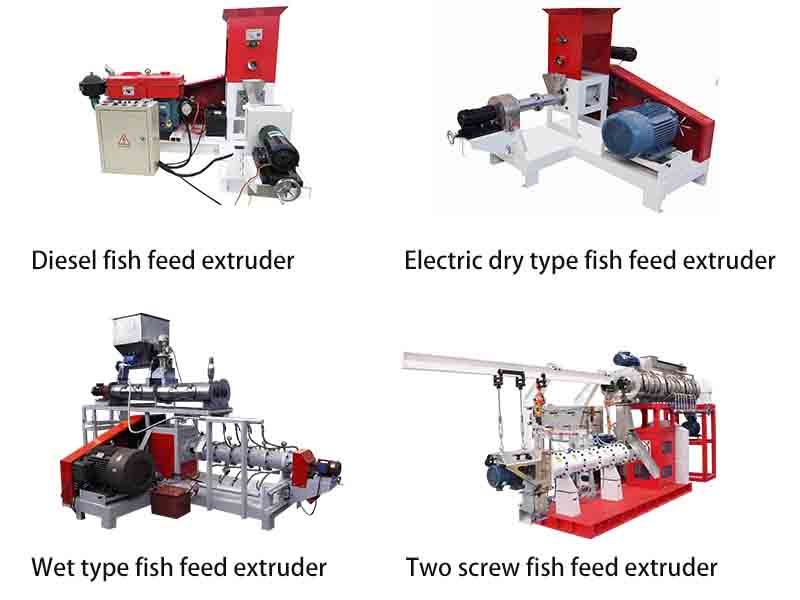

(1) The raw material adaptability of twin-screw extruder machine is wider, which can adapt to high viscosity, low viscosity, high oil content, high moisture or viscosity, oily, very wet, and some others in single screw extruder machine (SSE) Processing of slippery materials.

(2) The twin-screw extruder machine has fewer restrictions on the particle size of raw materials, can adapt to raw materials with wide particles, or from micro-powder to coarse-powder particles, and can also be adapted to single-screw processing.

(3) The twin-screw extruder machine can make the material mix more evenly in the barrel and can make the raw material get better stirring regardless of adding steam, water, and other auxiliary processing, and achieve the actual demand effect.

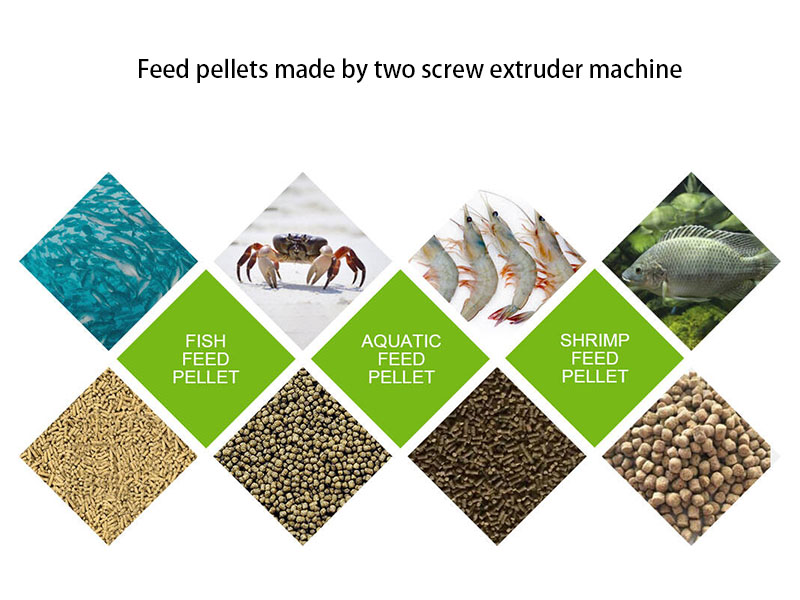

(4) The feed produced by the twin-screw extruder machine has better internal and external quality, can achieve a very good homogeneous state and make the molecular structure of the material evenly distributed, the surface is smooth during the extrusion process, and the product the particles have high uniformity and good uniformity.

(5) The feed produced by the twin-screw extruder machine has better curing and homogenization effect. Usually, the starch curing degree can reach more than 95%, so that the processed aquatic feed can be stable in water and the nutrients in the product will not be lost and easily digested. absorb.

(6) Under the same power, the output of the twin-screw extruder machine is higher, and the good mixing performance enables the heat obtained by the material to be homogenized in time, which accelerates the degree of maturation of the material, reduces the fluctuation of material temperature, and improves the extrusion and puffing. The output of the product.

(7) The product diversity and adaptability are wider, and it can process particulate aquatic feed, high-oil formula, high-moisture, high-cohesion products, and multi-color, sandwich, and special-shaped products.

(8) The process operation of the twin-screw extruder machine is easier, and the spindle speed can be adjusted according to the needs of the processed products. Due to the self-cleaning feature, the cleaning is very convenient, and there is no need to disassemble and assemble the equipment after each process.

(9) The wearing parts of the twin-screw extruder are lighter in wear. Usually, there is a misconception that the single-screw wears less. In fact, during the twin-screw extrusion process, due to the characteristics of stable material conveying and material flow, The wear of the material on the screw and the inner sleeve of the barrel is smaller than that of the single screw. Although the number of screws in the twin-screw extruder is one more, the cost of its accessories is still lower than that of the single-screw extruder.

(10) The production cost is lower. Due to the good operation stability of the twin-screw extruder, in the feed processing process, the startup cost is less, the waste of water and gas is less, the labor cost is less, the heat transfer efficiency is high, the yield is high, and the kilowatt-hour is low. The output index is high, the cost of accessories is also low, and the final production cost is still much lower than that of the single-screw extruder.

When we choose extrusion equipment, we should not only see that the price of the twin-screw extruder is higher than that of a single-screw extruder but also consider the comprehensive cost performance and the cost per ton of product produced.

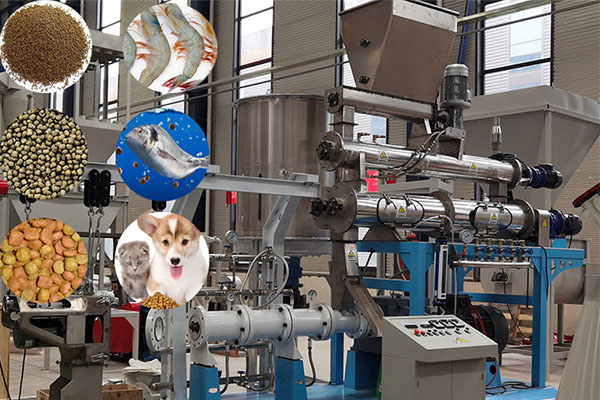

The technical performance and manufacturing level of Lima twin-screw extruder machines have reached an international advanced level. It can not only meet the needs of aquaculture feed in the aquaculture industry but also achieve high-cost performance. It is the best choice for the aquatic feed processing industry.

Back to List