What is a twin screw extruder?

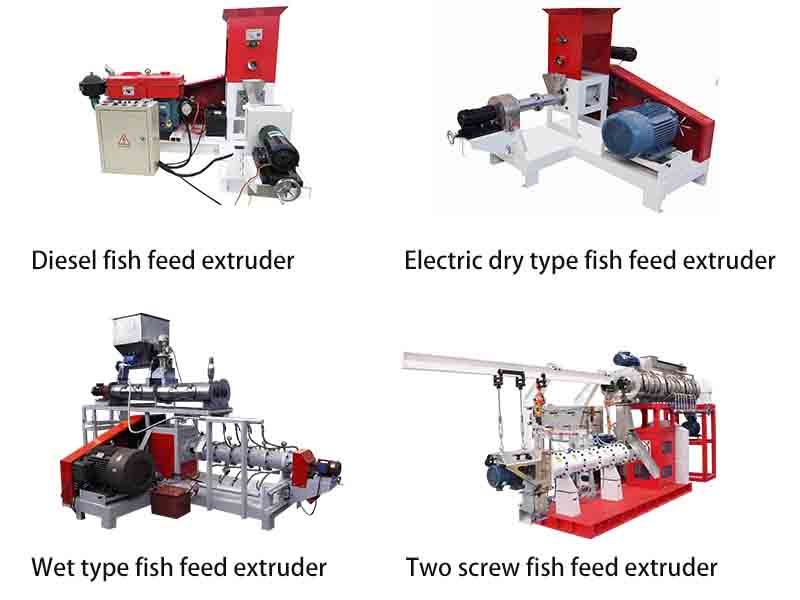

The feed extruder machines are divided into single screw and twin screw extruder. Today, let us talk about the twin screw extruder

- Firstly: Principle of twin screw extruder machine

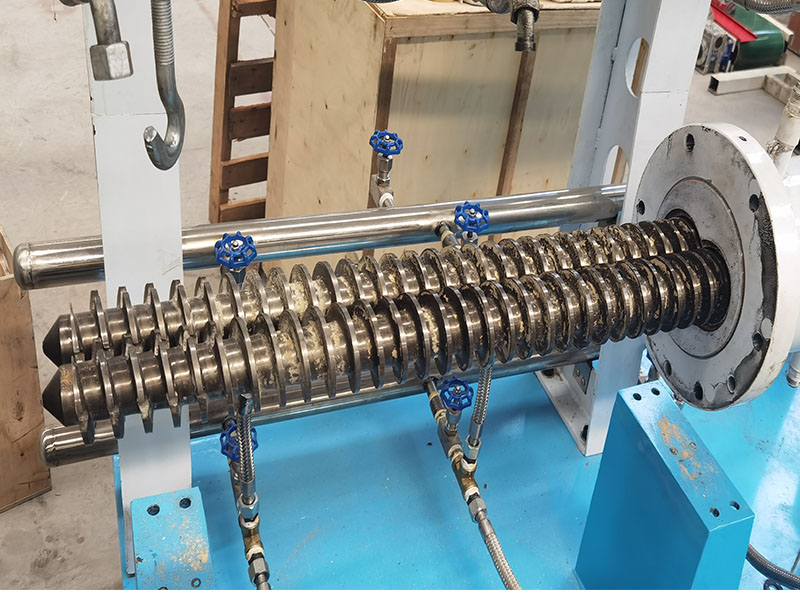

The twin extruder machine also called double screw extruder machine. Twin screw extruder is developed on the basis of the single screw extruder. In the barrel of the twin-screw extruder, two screws are arranged side by side. According to the relative position of the screw and the direction of the screw, it is divided into Non-meshing, co-rotation, non-meshing, relative rotation, meshing, co-rotation, meshing, and relative rotation.

- Secondly:Compared with the single-screw extruder, the twin-screw feed extruder machine has many advantages in the production process

1) Double screw extruder can adapt to the processing of high-viscosity materials, low-viscosity materials or high-moisture and high-oil formula products

The fully meshed co-rotating twin-screw extruder greatly improves material conveying, pumping and mixing characteristics. Although the twin-screw extruder is also a drag flow machine, it has the added function of a positive pressure pump because its 2 screws rotate in the same direction and are fully meshed. This makes the twin-screw extruder can be used to transport both high-viscosity materials and low-viscosity materials.

Therefore, there are many kinds of feeds processed by the twin-screw extruder, which can be adapted to the processing of high-viscosity materials, low-viscosity materials or high-moisture and high-fat formula products. In terms of aquatic feed, such as fish and shrimp feed pellets, as well as river eel, ornamental fish feed, etc., need to use twin-screw extruder, especially for particulate aquatic feed (0.5-1.5mm in diameter), high-fat aquatic feed and production capacity Small but constantly changing feeds must be produced by twin-screw extruders.

2) Ability to process diverse combinations of raw materials

The biggest feature of the twin-screw extruder is that it can mix various raw materials regardless of their composition. Thus, such diverse components as grains, soybean meal, animal meal, fresh meat, fats, nutrients, proteins, vitamins, starches and wet fish residue can be easily processed.

The feed extruder machine also could be used to produce pet food feed pellets, which is called pet food extruder. In pet food processing, the main components of pet food are generally composed of grain meal (such as wheat flour) and animal meal with higher protein content, fresh meat and fat. In the process of dry pet food processing, when the fresh meat content is as high as 20% to 30%, intense mixing and kneading are required during extrusion, which can only be accomplished by a twin-screw extruder.

Because of the mutual kneading and extrusion of the twin-screw, even if the raw material is high in oil, it will not stick together and affect the operation of the machine. Compared with the single-screw extruder, the twin-screw extruder can add Almost twice as much fat is added to pet food formulations, so formulations can contain more than 20% fat. This not only improves the quality of the formulation, but also slows down the wear and resistance of parts, reducing production costs.

3) The twin-screw extruder has self-cleaning function

At the same time, the twin-screw extruder has a self-cleaning function. After the feed is processed and produced, the twin-screw extruder will automatically extrude the remaining internal materials out of the machine, and there is no need to unload them one by one for cleaning, which greatly saves time.

Lima feed machinery is twin screw extruder manufacturers, we have floating fish feed / shrimp/crab/aquatic feed and dog/cat/pet feed twin screw extruder for sale. Welcome to contact us foe more details of feed extruder machine

Back to List